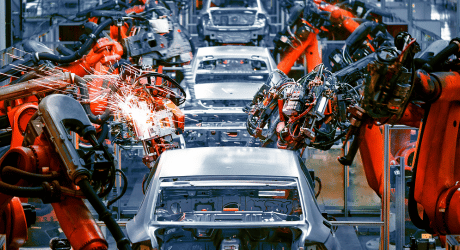

Automobile industries use PLC, SCADA and HMI for manufacturing processes. PLC’s improve the way of manufacturing and by using plc’s safety of the equipments and human beings are enhanced. In the operation of blanking, stamping, body building, painting, engine assembly, body assembly , quality control and in dispatch system automation technologies are being used. Automation can help in the improvement of manufacturing velocity across the automotive supply chain.

Automation offers a fully integrated approach to the production of beverages – from the receipt of raw materials through the delivery of packaged products. This approach ensures that you can efficiently deliver a diverse mix of quality, safely produced beverages at the lowest per-unit cost while not sacrificing taste, uniformity and consistency between plants. Thus automation will be used in the conveyor systems to drive the bottles, counting the number of bottles, In filling process of the beverages .

Automation provides complete automated manufacturing solutions, including power, process, information, and service and support, to help operate safe, efficient plants that deliver consistent high-quality products. In the area of food packaging, fragmentation and agitating automation technologies are being used. Only through flexible manufacturing and greater asset utilization ever-evolving demand can be met and that will maximize the return on automation investment

Automation are being used in bulk carrier, rig, tug, tanker, supply vessel and so on in the marine sector. When it comes to designing high-performance, cost-effective diesel electric vessels are necessary. Today’s ship builders are facing daunting challenges and for each new challenge there is a solution that can withstand the rigors of a marine environment. Commercial and military vessels around the world rely on automation solutions to optimize performance.

Continuing evolution of materials and process technologies has created a need for a new approach. For applications in primary or secondary production areas, automation solutions help produce higher quality products with consistent metallurgical properties, while boosting yields and minimizing energy costs to reduce the cost-per-ton. Automation technologies are being used in mining areas of metals and so on.

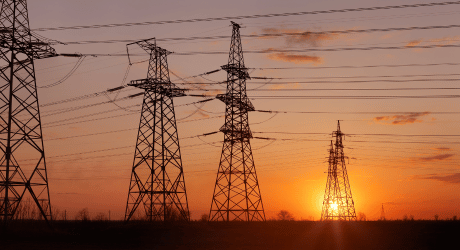

As a power provider, goal is to cost effectively and reliably produce electricity. So there is a challenge to improve operational efficiencies despite aging assets, increasing environmental regulations, and meet these demands with a shrinking pool of resources and experienced workers. Automation has the technology and solutions to mitigate the potential risks associated with these challenges and helps in minimizing manual errors in managing power production, boiler management, power distribution..thus it offers integrated control, power, safety and information solutions in one open, scalable architecture for complete plantwide control – for conventional or renewable energy generation.

Automation is helpful in materials packaging, material transfer, automatic storage and in retrieval systems. Every stage of the mining operation can be improvised with automation technology. To increase throughput and lower operating costs – from the extraction site through the processing plant. Increasing personnel safety with autonomous mining solutions and remote control and monitoring of equipment and processes. Automation optimizes energy use and reduces mechanical equipment wear and tear.

Automation helps in streamlining manufacturing processes while minimizing water, energy and material costs; improving product quality, productivity and capacity while reducing downtime. Automation is used in cutting, unwinding and rewinding of paper rolls, then in lamination and slitting processes.Executing real-time control and maintaining critical process parameters to diverse demands can be achieved through automation technology.

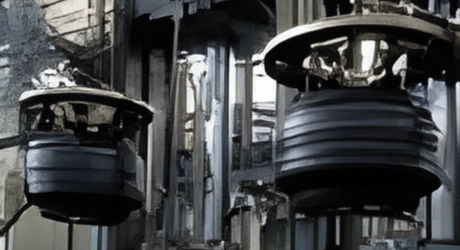

Automation will be used in the process of tire manufacturing with accuracy. Production processes can be enhanced efficiently with the help of automation. so that the tires can be produced more efficiently while consuming less energy and reducing waste.A full-spectrum approach provides easier integration and standardization across plants and throughout the life cycle of the tire-production process. These automation solutions enable the suppliers to adhere to safety and regulatory requirements, as well as integrate efficiencies that improve productivity and quality, and reduce total cost of ownership.

Automation provides a wide range of multi-disciplinary services - including extensive access and insulation support to the chemical, petrochemical and polymer plants. Thus automation is the integral part of chemical plants.Chemical dosing system is the plc based system which mixes accurate composition of chemicals. Automation helps in providing world-leading safety performance and to run smoothly and cost-effectively the chemical plant. Automation helps in managing all the parameters in the plant.

Automation is very helpful in the cement industries. In various areas of processing such as ball mill application, kiln and cooler application, vertical roller mill application automation is getting used. Thus through automation expert control and supervision is possible.

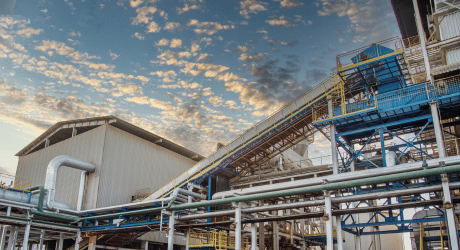

Sugar Automation Solution includes Field Measurement devices, Base Process Control equipment, Advanced Plant Management Optimization and Control software and custom algorithms for applications like batch pan control. The integrated approach adopted in automation solutions and deployment lead to benefits not only in the Sugar Plant but also in allied areas viz. Cogeneration Plants and Alcohol plants.

In wind turbine, several areas can be automated to lift the efficiency of the wind turbine, to improve ergonomics or to reduce the weight of the wind turbine by replacing solutions that are more complex and already needs to be controlled from a central control point.thus automation helps to maintain and manage wind mills.

Automation is used in the areas of filling, labeling, bagging, palletizing the products in different industrial sectors. Thus through automation efficiency can be increased by decreasing the energy use. Especially in packaging industry monitoring and making report for the products packed per hour to day is important, which can automatically be managed by automated systems.

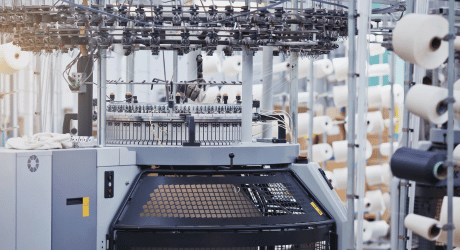

In the textile manufacturing process, automation is one of the major key to quality improvement and cost competitiveness. Automation has taken place in all the processes involving textile manufacture i.e. cotton picking, ginning, spinning, weaving, and processing and even to some extent in garment making, resulting in enormous gains in productivity and efficiency.